FALL INCREASER-MOODY EJECTOR TURBINE WEB PAGE

There are three, classic forms, of fall increasers.

Clemens Herschel (the inventor of the Venturi Meter) designed a head increaser where the discharge end, of a vertical, conical draft tube, was inserted into the throat of an enormous, horizontal, Venturi meter. The upstream end of the Venturi protruded into the impoundment and was gated. Its exit was into the tailrace. During normal flows, the entrance to the Venturi was closed, with its gate. The turbine discharged through the draft tube, into the venturi and out into the tailrace. During freshets, when the tailwater was high, the gate at the mouth of the Venturi was opened. The excess floodwaters flowing through the Venturi, created a vacuum in the throat of the Venturi. Since the turbine draft tube was discharging into the Venturi throat, the turbine saw an increased pressure drop across its runner. The lost head created by the elevated tailwater was effectively recovered.

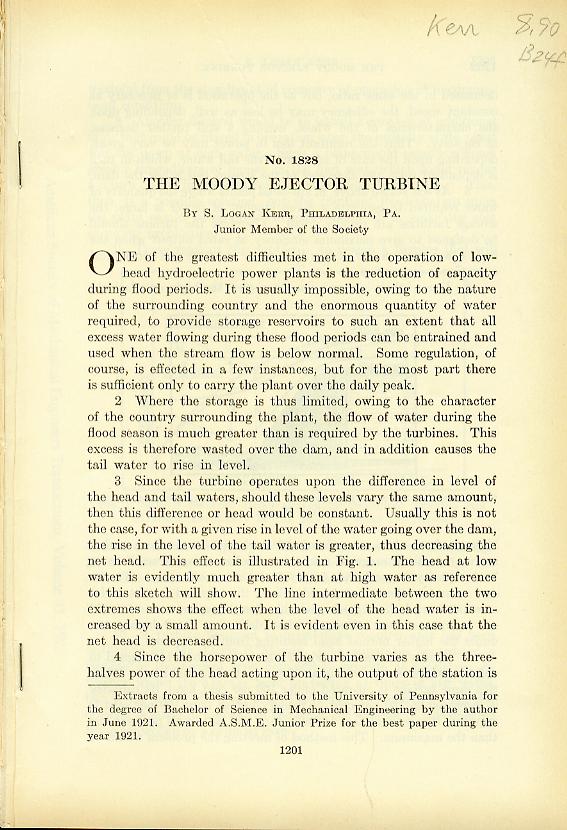

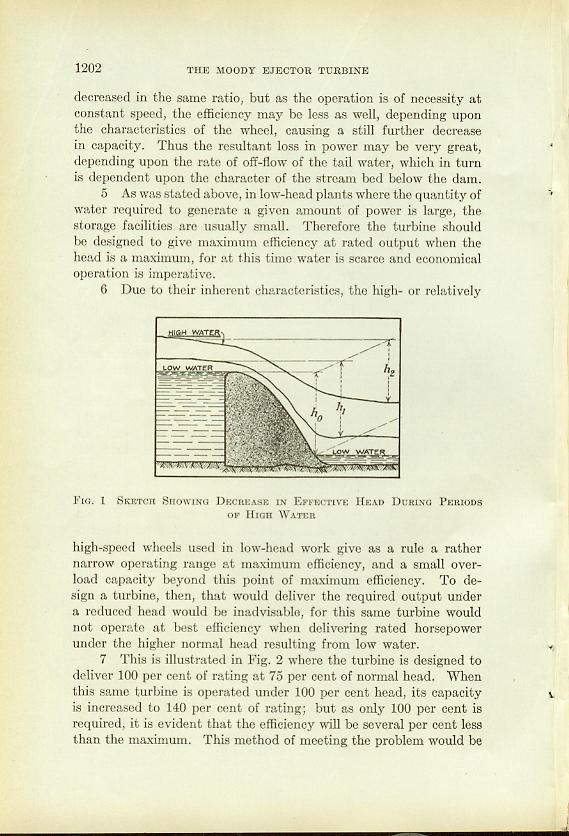

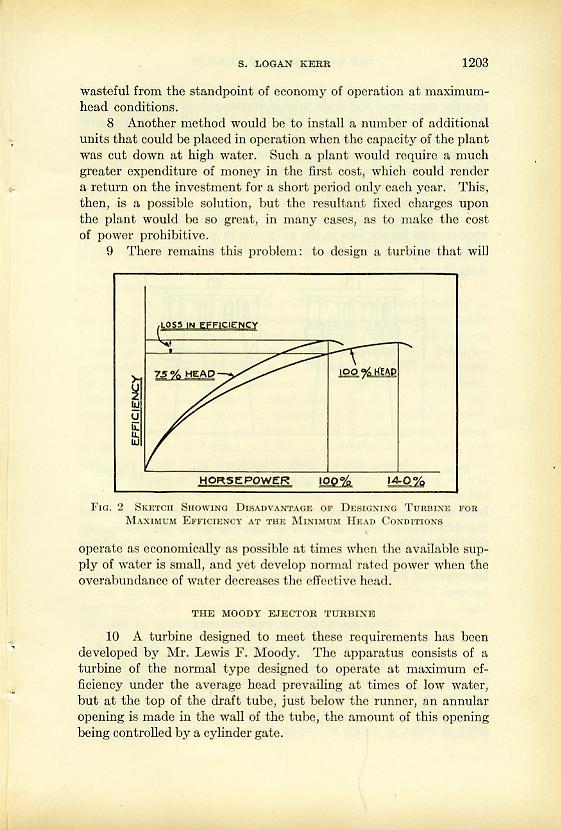

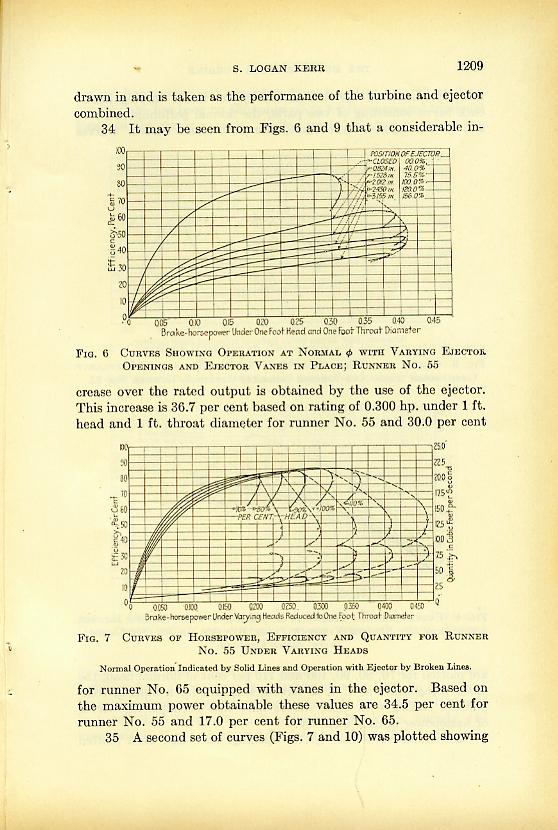

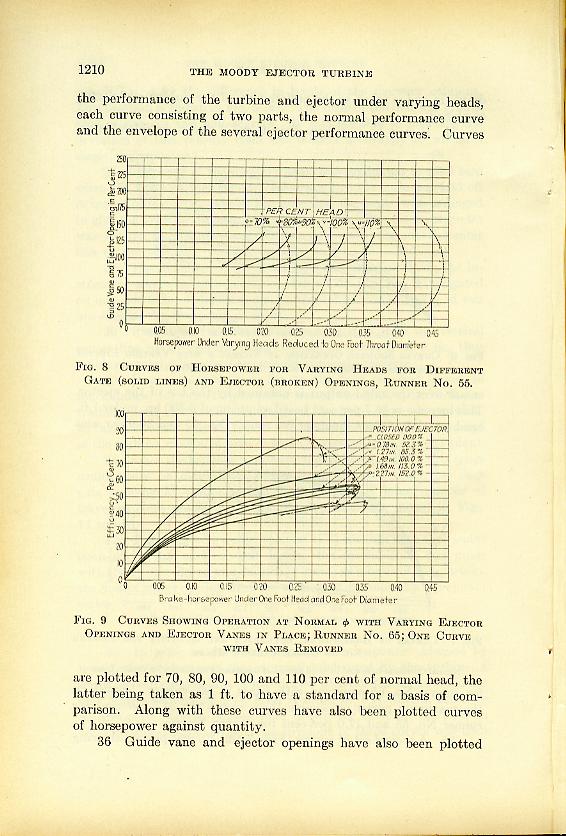

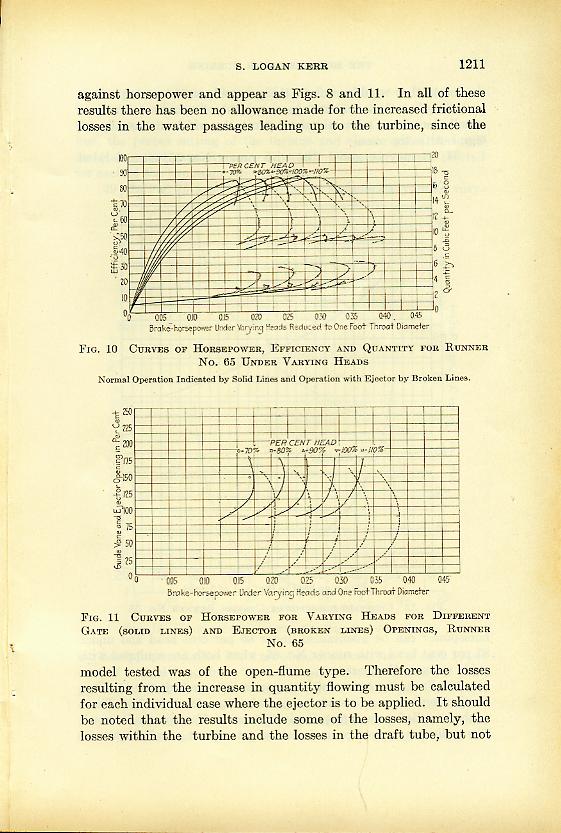

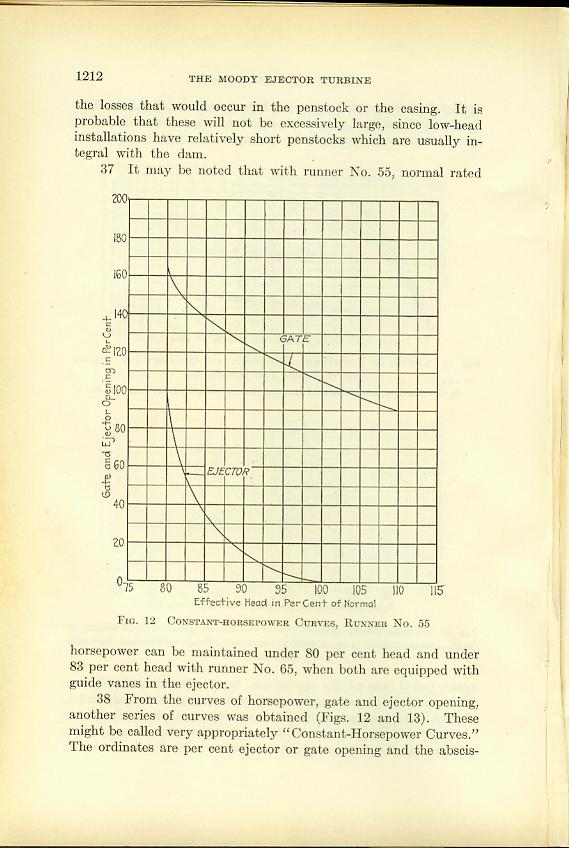

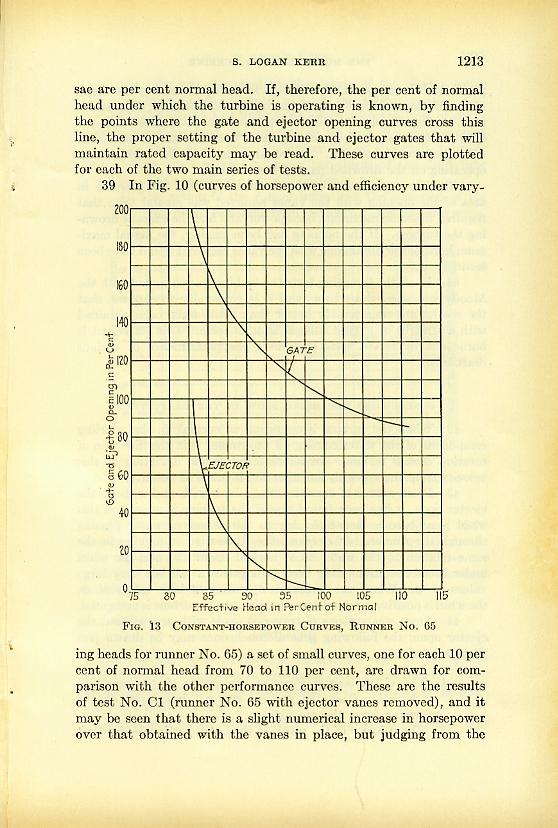

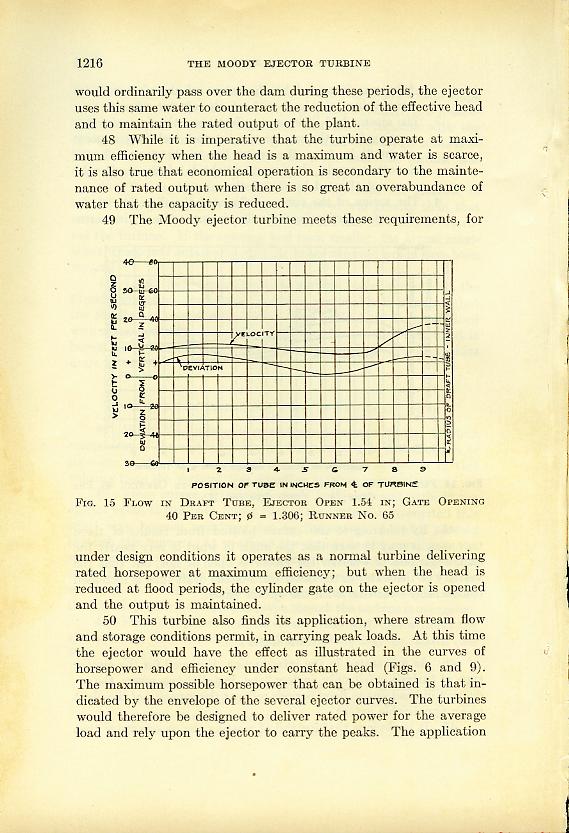

Moody designed his ejector turbine. In Moody's design, the turbine draft tube has an annular opening cut in the top of the draft tube. This opening is surrounded by an annular guide vane. A cylinder gate seals the annulus when it is not being used. During normal operations, the cylinder is closed and the turbine discharges through the normal draft tube. During freshets, the cylinder gate is opened and the discharge through the draft tube is increased. The additional water increased the pressure drop across the runner. Henry Ford installed one.

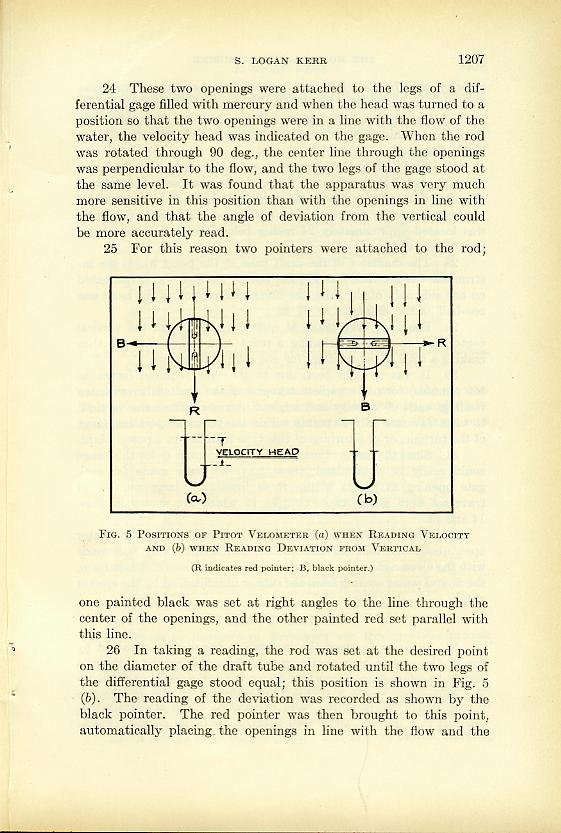

The last design utilizes the water surface suppression created by an ogee curved spillway. The powerhouse is designed so that it is adjacent to the spillway. The powerhouse discharges into the trough of the ogee spillway. At all spillway surcharge flows, the tailwater exiting the powerhouse, remains suppressed. The total head across the runner remains constant.