Kaplan Turbines Website:

March 7th, 2012, Over the years, Davis and I have rebuilt a number of Smith Kaplan turbines. We have rebuilt, the Valley Paper Kaplan, the Hagley Museum Kaplan, Jerry Olsen's Kaplan, the Union Twist Drill Kaplan and the Madison Kaplan. I thought you would enjoy some photos from these jobs.

Here the Hagley Museum, Kaplan, pressure, case is being installed in the old foundation.

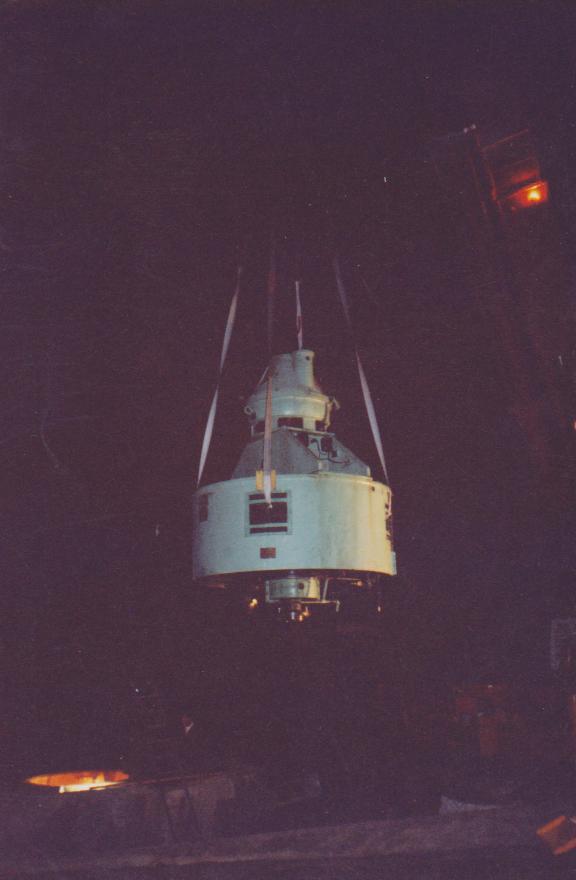

Here, the Hagley Museum Kaplan is flying through the air ready to be installed in its pressure case.

Here, the Hagley Museum GE Generator is being flown to its final location.

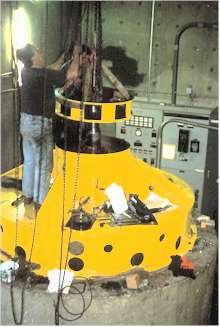

Here, the Valley Paper Kaplan is being flown through the nurses' cafeteria window. Davis Hobbs is holding the tag line.

Here, Davis Hobbs is doing the final rigging to lower the Valley Paper Kaplan down the hole in the nurses' cafeteria room floor.. We did this at 2:00 am to avoid the inspectors!!!

Here is the Valley Paper turbine stuck in its throat. It was 4:00 am and I told Davis we needed to go home and sleep. We had previously measured the throat diameter in order to tell the machine shop what diameter to turn the blade tips. We were so poor we did not have a 60 inch inside mike. We bought a 3/8 inch turnbuckle we special ordered a 36 inch piece of left hand and right hand threaded rod. We inserted them into the turnbuckle. Davis and I crawled down into the scroll case. While laying on our sides I had him hold one end of the turnbuckle, threaded, rods against the throat. On the opposite end, I slowly adjusted the turnbuckle up and down and back and forth until I felt comfortable with the measurement of the inside diameter of the throat. We locked the turnbuckle with left and right hand nuts. I brought the faux calliper to Rice Barton in Worcester, MA. I told them to turn the new bronze blade tips to a 1/32 inch diameter less than the faux calliper reading. They did it. When we lowered the runner into the throat, it stuck in the throat. The next afternoon we came back. I was very depressed and worried. Davis, God bless him, put his foot on the coupling and gave the shaft a nudge. To my astonishment, the runner dropped down. We let off on the chain fall and lowered it into place.

Here, we are hand turning the main shaft on the Centennial Island Kaplan. The generator thrust block (top hat) had become loose on the shaft and rocked back and forth. The owner had received an outrageous price to disassemble the generator, press the rotor shaft out of the rotor hub and turn the shaft concentric again. We did it in about six hours with five guys. When the unit was reassembled, we put a quarter on edge and it did not fall over. Before we did the work, the unit was shaking the powerhouse floor.

Another view of hand turning the Centennial Island generator shaft. Warren Fay, "The Wizard" is supervising the work. It was Warren's idea to hand machine the shaft. He made a special cutting tool from the hub of a large cast iron pulley.

Here is a photo of the special turning tool Warren Fay made from a cast iron pulley hub. Note how rusty the surface of the shaft is. Where the shaft is rusty, the thrust block was supposed to be pressed on with a 0.004 inch interference fit. The fit had become so worn and loose that moisture entered the interface and rusted the shaft.

Here, I am dismantling the upper bearing on the Centennial Island Kaplan

.

Here is the turbine pit for the Madison, ME Kaplan. Will spent a week prying this unit from solid concrete.

This is the lower level of the Madison, ME Kaplan unit.

Here is the generating room floor of the Madison, ME unit. Will has started to dismantle the Woodward Governor.

Karen and I took the grandchildren to Santa's Village this weekend. We stopped at Littleton and visited with Tommy Clark. Here are some interesting photos.

Ed Clark's Littleton Smith Kaplan. The Clarks are perfectionists!! Behold the iridescent green bright work. What a beautiful unit!!

This is a Lombard Type "V" hydraulic governor. Note the Honeywell damper motor being used as a pond level controller. It is chain driven to the gate control shaft. A 100 ohm pot at the dam is operated by a float. As the level of the water rises and falls, the resistance of the pot controls the position of this slave motor.

Here is the 100 ohm pot being controlled by the float rod located at the dam. The Clark's installed a Andantex right angle gear box as a reduction damper drive to the 100 ohm pot. The SO cable runs down to a heat lamp in the stand pipe to prevent it from freezing in the winter months. Frazil ice is a horrendous problem at this station. The Ammonoosuc River drains the west flank of Mount Washington. The watershed is extremely steep and ambient temperatures of -40 degrees C/F are not uncommon. Tommy uses a Roots, high volume, low pressure blower to clear the frazil ice from the racks.

The Littleton Hydroelectric Plant owned by White Mountain Hydroelectric.

The carcass of the once mighty S. Morgan Smith Kaplan. This is a 120 inch runner. The copper maggots stole the pole pieces and stripped the stator. I have coveted this machine for 35 years. When I first saw it in 1978 you could have started it back up. So sad!

Alternate view of this sad old lady! Note the roof has finally gone