Smith Kaplan Web Page

I am a great fan of S. Morgan Smith turbines. Davis, Ken and I have made extensive repairs to six of these units. We fabricated new blades (aluminum bronze) and new wicket gates and totally rebuilt the 60 inch unit at Valley Paper in Holyoke, we removed and reinstalled the 51 inch unit that was installed at the Hagley Museum in Delaware. This was one of Paul Smiths Units and was originally installed to power the first Winter Olympics at Lake Placid, New York in 1934. We brought it back to Thorndike, rebuilt it and installed it in Thorndike. We have made extensive repairs to the Centennial Island 60 inch unit. We have rebuilt the bearings at the 60 inch unit located at L P Athol Corporation, in Athol. MA. I have worked on the 36 inch unit at Littleton, NH. We worked on the 51 inch unit at American Optical in Southbridge, MA. Both AO and LP Athol were electric Kaplans with the blades driven by selsyn motors.

The Kingsbury thrust collar was loose on the generator shaft at Centennial Island's Kaplan Turbine. Jerry Olsen did not want to pull the generator rotor. The Wizard bored out the collar and repaired it by making an insert. We pressed the insert into the collar and bored it undersize. We fabricated a hand turning device from an old cast iron pulley. Warren installed a carbide cutting, tip that he could adjust, on the inside bore. We had Ronnie Johnson, Marshall Smith, Justin and Matt turn it by hand while Warren supervised. The finish was excellent. We reassembled the unit. You could stand a penny on edge when the unit started up. Jerry Olsen said it was the smoothest the unit had operated since it was installed!

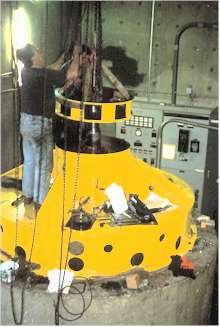

I am rigging the bearing chamber cover that closes off the General Electric spring bed bearing. Pulling the runner at Centennial Island.

Davis inspects the new aluminum bronze blades we had cast and machined for Valley Paper

The valley Paper Kaplan being lowered into its throat ring.

The end