Collins Bascule Dam Web Page

Since the most appropriate and most economical design, for the Lake Anastigunticook Dam Replacement Project, is a hinged, crest, gate (Bascule Gate) it is appropriate to investigate a similar design already constructed. Such a dam, is the Collins Hydroelectric Project Dam (FERC L.P. No. P-6544-MA), owned by Swift River Company, located on the Chicopee River, in Wilbraham, MA. Swift River Company has generously allowed the use of both photographs and drawings of the dam and of its recent rehabilitation.

Figure One: Collins Hydroelectric Project. Panoramic view of dam taken from beneath the highway bridge.

The original dam was a timber crib structure, built by the Collins Paper Company, in 1872. The dam spanned the Chicopee River and conveyed water, through a power canal, to waterwheels, located in the basement of the brick mill. As the timbers reached their useful life, the structure weakened. On March 7th, 1979, a freshet that peaked at 10,500 cfs, caused a catastrophic failure of the timbers and the dam breached.

In 1982 Swift River Company, filed an ownership exemption, with the Federal Energy Regulatory Commission, to rebuild the dam and install a hydrogenation plant. The redevelopment scheme included abandoning both the power canal and the original timber crib dam design. The proposed project included a power plant, constructed integral with a Bascule style spillway. The former power canal was filled in. The river bed, downstream of the dam, was dredged to allow the head, at the exit of the old tailrace, to be brought upstream to the outlet of the new turbines. Two ESAC, 650 KW, pit bulb, turbines were installed in the powerhouse.

In plan view, the Collins Dam is a two section, dogleg. The primary length of the dog leg consists of a short Bascule gated section that extends from the north river bank, 56 feet to the powerhouse forebay wall, the powerhouse, and a much longer, twin, 64 feet long, Bascule gated spillway that extends 128 feet to the abutment of the former power canal. The dam then swings 90 degrees and a lengthy canal spillway, runs parallel to the riverís edge, to the state highway bridge. Beyond this point, the former power canal has been completely filled in. The combined hydraulic capacities, of the fully depressed Bascule gates and the fixed canal spillway, with the headwater at the top of the abutments is 12,000 cfs.

In section, the dam has a rock filled base. The base is capped with heavily reinforced concrete. At 16 foot intervals, a heavy, steel, hinged, I-beam, needle, operated by a massive hydraulic cylinder, is attached to the concrete cap. The adjacent needles have southern yellow pine timbers stacked in their grooves. These timbers create movable panels that are raised up and down by the hydraulic cylinders. This allows the headwater elevation to remain constant with varying river flows. In between each four panel spillway is a robust concrete pier. Rubber seals are used to reduce leakage between the movable panels and the concrete piers. A heavy, steel, sheet pile, cutoff wall was driven 30 feet down into the river bottom upstream of the rock fill. The space between the top of the sheet piling and the rock fill was filled with air entrained concrete fill. Heavy riprap was placed on the downstream slope. A concrete pump was utilized to fill the interstices between the riprap with air entrained concrete. Automatic, unmanned operation was originally controlled by direct current, ice cube relays. These were replaced in 1989 with an Allen Bradley PLC (programmable logic controller). Fail safe operation was achieved by incorporating internal relief valves in the hydraulic manifold. In the event that the PLC and/or hydraulic system failed, during a flood, the relief valves are adjusted to open with a predetermined water surface elevation over the boards. The relief valve for each panel is set slightly higher then its successor panel. This allows the boards to fail in a controlled, progressive, cascade. Although this system was tested, it has never been used. The PLC, with its backup battery supply, has performed flawlessly.

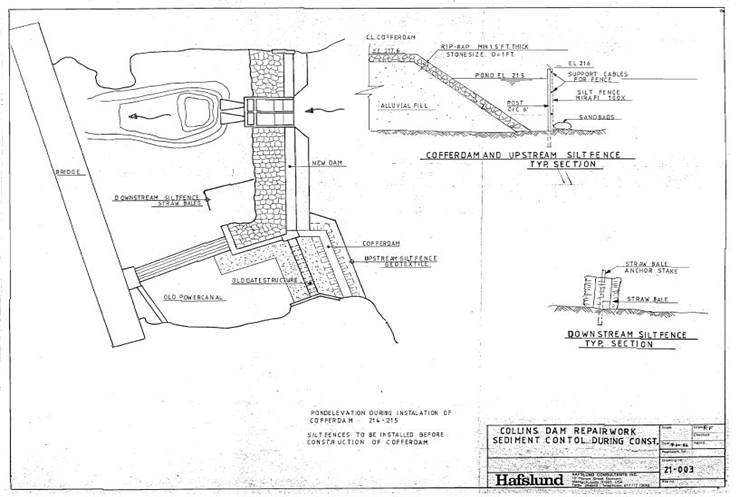

Figure Two: Plan View of Collins HEP Project.

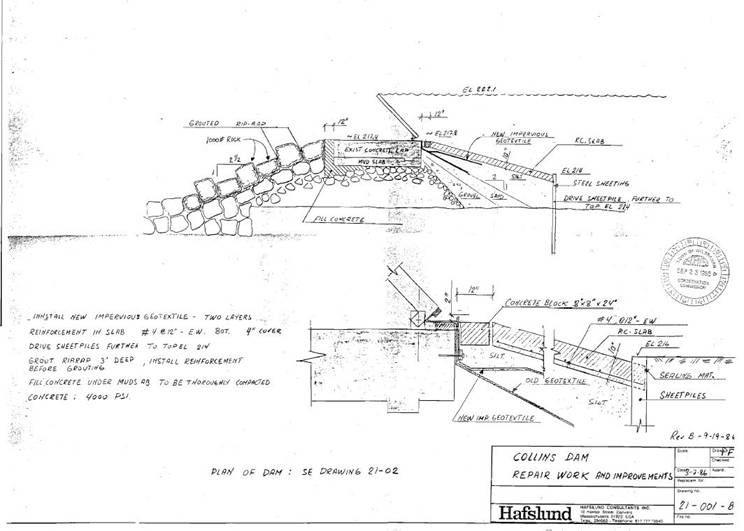

Figure Three: Sectional view of Collins HEP Spillway.

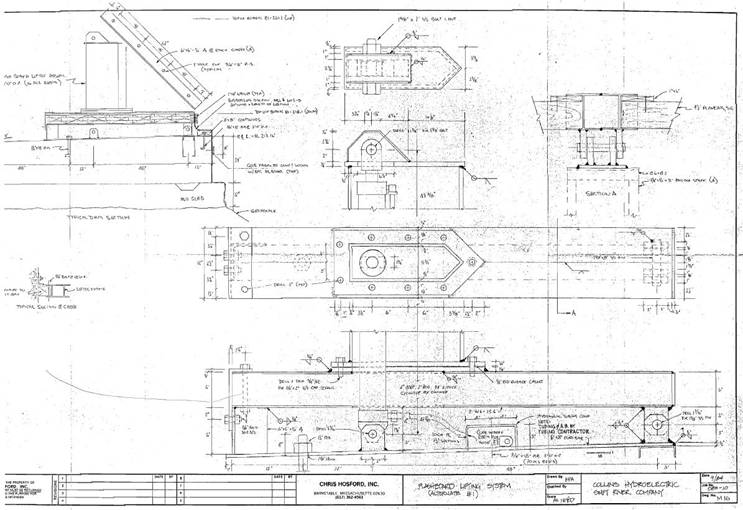

Figure Four: Detail drawing of Collins Bascule Gates

The project was constructed in 1984. In the summer of 2006, after 33 years of continuous operation, the Bascule sections were rehabilitated. The old wood was removed, the needles were sandblasted and painted. The hinge pins were replaced. The hydraulic cylinders were rebuilt. The cylinders needed new seals, new cylinder tie rods and new pins. They were sandblasted and painted. The hydraulic lines were replaced with all new stainless steel lines. The hydraulic control manifold and hydraulic powerpack were replaced. An Allen Bradley, SLC 500 programmable logic controller was installed to replace the ice cube relay automatic pond, level, control loop. The cost of the rebuild was $ 260,000, including labor.

Figure Five: Summer of 2006 rehabilitation. Note all the wooden panels have been removed for replacement

Figure Six: Summer of 2006 rehabilitation. Note all the wooden panels have been replaced. The blue barrels in the background are the boater safety buoys.

In conclusion, the Collins Dam serves as a model for the proposed Lake Anastigunticook Dam Replacement. It is a simple, inexpensive structure. It has a moderate life span. The life span can be easily prolonged with simple maintenance. It has flawlessly functioned for 33 years.

The construction of a Collins type dam, at the proposed dam site, at Lake Anastigunticock is simplified. This is because the leveling slab can be poured directly on the underlying ledge. This eliminates the rock filled section. The use of a PLC based control system allows the lake level to remain constant. This is achieved by lowering the timber panels with the hydraulic system as flood flows increase. Once the panels are fully depressed, the hydraulic profile reverts to channel control exerted by the historic channel walls. The hydraulic system is charged with water soluble, environmentally friendly oil.

The following photographs depict the summer of 2006 rehabilitation:

Figure Seven: Hydraulically controlled, I-Beam, Needles. Note the rectangular caps that the cylinders thrust on. The caps allow the boards to fully depress. They also protect the cylinder from debris flowing over the dam crest.

Figure Eight: A close up view of a hydraulically controlled, I-Beam, Needles.

Figure Nine: Note the laminated panels being held together with stainless steel, threaded rod. This is a simple, durable method of construction

Figure Ten: The downstream riprap being stabilized with air entrained concrete.Up lift on the finished riprap was prevented with subsurface drains.