Tannery Rebuild Web Page

My son, Will Fay, applied for and received a grant from the Massachusetts Technology Collaborative, to replace and append equipment at our Tannery Pond Hydroelectric Facility. We replaced an inappropriate Leroy Somers tube turbine with two smaller Francis turbines. The following photos depict his trials and tribulations with the reconstructive efforts. We replaced the tube turbine with two James Leffel turbines. The larger unit is a Leffel 18 inch "Z" that was originally installed at the Shaker Mill Dam in West Stockbridge, MA in 1937. We had purchased the turbine and generator from the Town of West Stockbridge through the efforts of our good friend and mentor Bill Munch. The generator needed new bearings, new windings and new stator iron core. My good friend Tony Rossario of Independent Electric Mechanics, 139 Henniker Street, Hillsborough, NH 03244-5527, (603)464-3869 rebuilt the unit to his customary outstanding excellence. It is beautiful and is better than when it left the GE factory in 1937. The Leffel "Z" needed new gates, a new runner, a new throat ring and a new shift ring. Shanak Foundry & Machine Company, 1325 Churchill Street, Waupaca, Wisconsin 54981, (715)258-7421 supplied a new 18Z runner and the requisite gate case components. Will Fay ran the 60 inch Bullard vertical turret lathe and machined the new shift ring and throat piece. Marge Bailey turned the new gate spindles. Hole Specialists Inc., 51 West Street, Ware, MA, (413-967-7100) gun drilled the new wicket gates. Gary Houlihan, 413-283-2383, machined the wicket gates to the correct height. Warren Fay, "The Wizard" of Dansons Machine, (413)-244-2794, was machining coordinator. Chris Krueger welded up the two generator support structures. Dave Flynn and Jay Lyons installed the two units in the powerhouse. Please enjoy the photos. God bless my people.

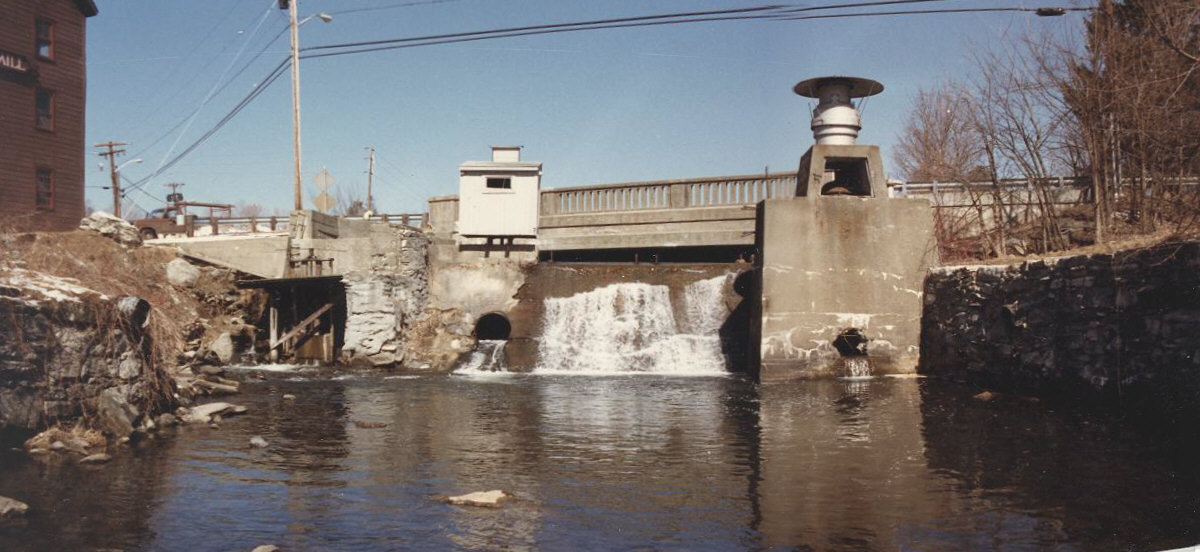

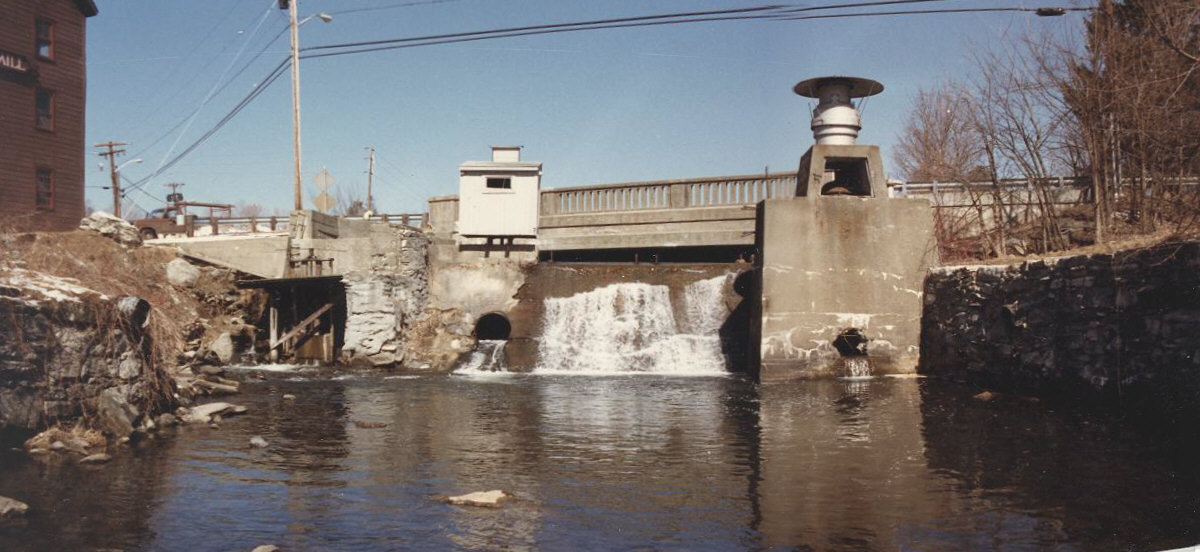

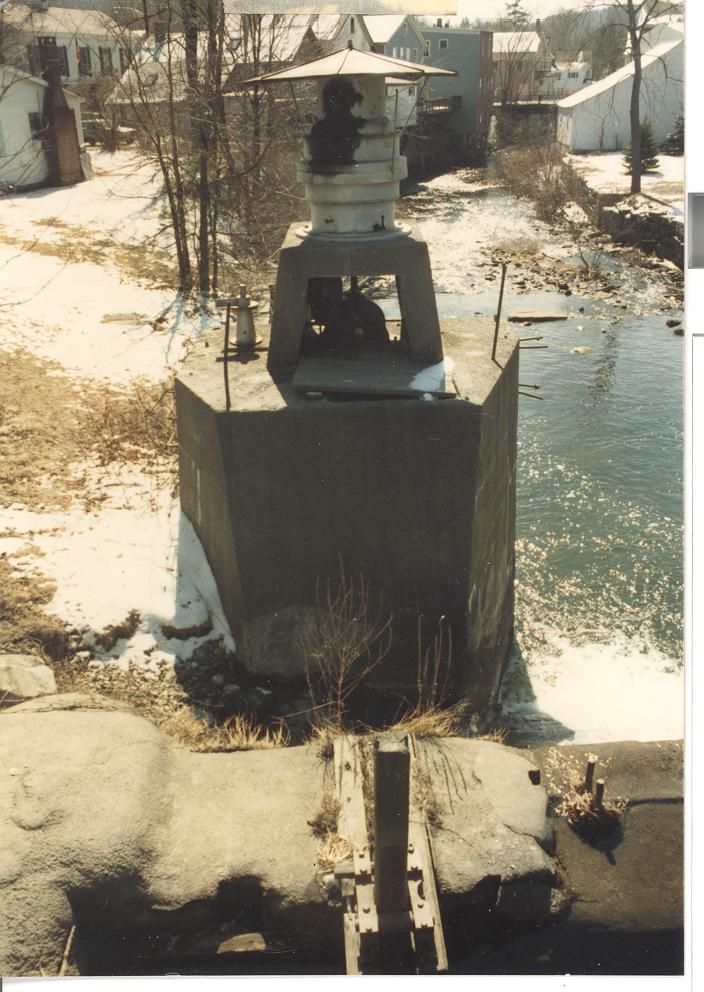

Here is the Leffel 18 Z turbine and GE generator unit in its original location at Shaker Mill Dam in West Stockbridge, MA. This photo is circa 1988. Note the funny looking sun hat on the generator that the Town installed in an attempt to keep the unit dry. This is the only known unit that was installed without a powerhouse super structure. As a result of all the moisture, that the generator was in contact with, the generator needed both the copper windings replaced and all the stator core stampings replaced. Subsequently, the Town razed this dam and powerhouse and installed a new dam.

Another view of the original installation looking downstream. Note the odd gate stand to operate the wicket gates by hand. This unit never had a Woodward Governor to control the gates.

The Leffel Z as we found it at Balgen Machine in West Stockbridge, MA. Ironically, the only pieces we used in this photo were the quarter block housings and the double bell crank. We replaced the runner, the wicket gates and all of the pins and bushings. We did reuse the turbine shaft.

The General Electric, 277 rpm, induction generator. It is sitting at the highway department in West Stockbridge, MA. Note the gate lifter that used to be used to open the low level outlet. Weight of the rotor is 1450 #s, weight of the Z runner and shaft is 500 #s, weight of the stator is 2100 #s, weight of the top bearing housing is 900 #s.

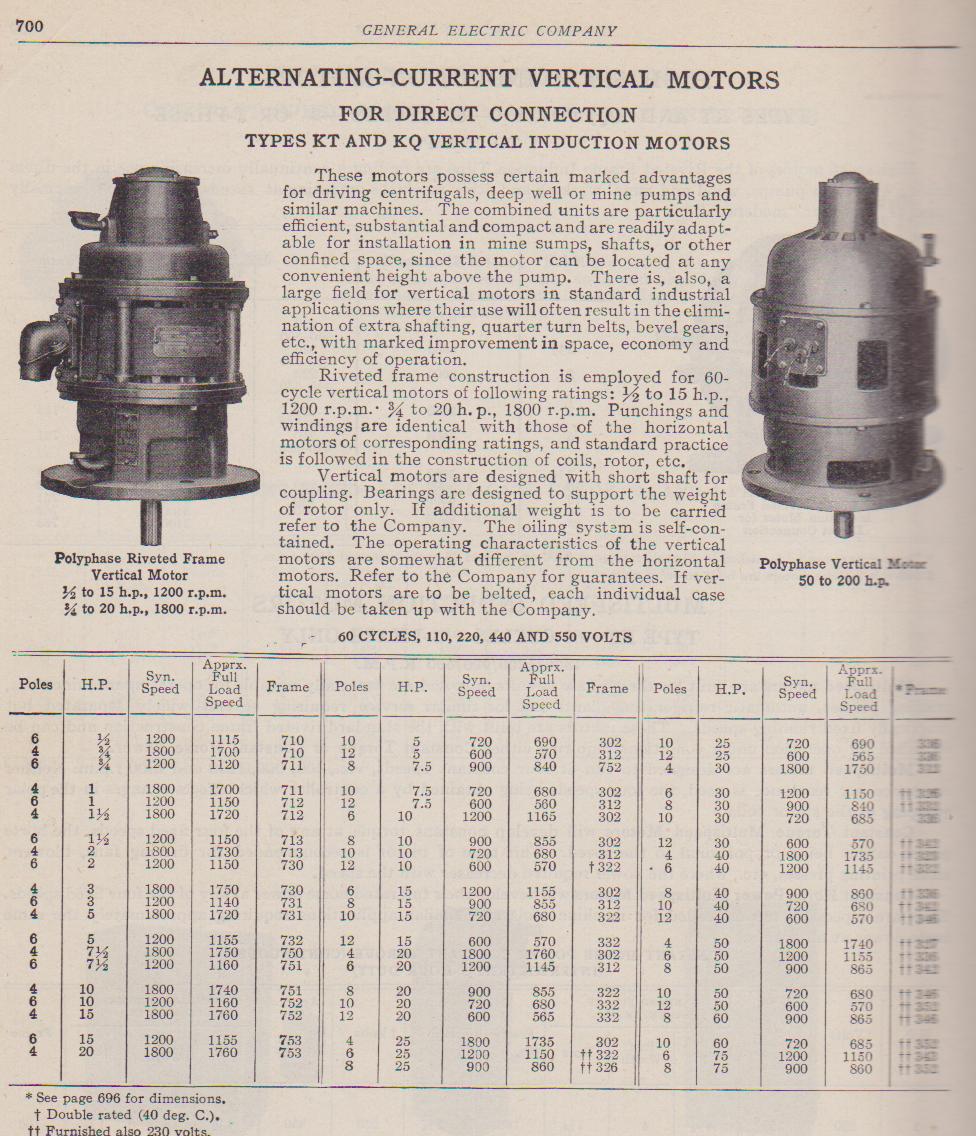

This is a page out of the 1925 General Electric Catalogue, No. 6001A that describes the generator. It is the unit on the left. It is described as a vertical induction motor. There is little difference between an induction motor and an induction generator. Please refer to the learned treatise on this subject by Mr. Nigel Smith that is found on the side bar: Motors as Generators for Microhydro, Nigel Smith. This generator is interesting in that it utilizes the smallest GE spring bed bearing that I have encountered. Please refer to the side bar: GE Springbed Brg.

Bringing home the gold!! Notice the chunk of iron missing from the gatecase. We had Bob cast another one.

You are looking at the cylinder gate for the tube turbine. Will subsequently cut up and removed this cylinder and removed the tube turbine.

Will is down in the pit cutting up the cylinder gate.

Looking down into the waterbox (pit) with the cylinder gate removed. The water is pouring over the edge of the thimble we installed that housed the French tube turbine.

Good bye French tube turbine!!

Will and I rigged the French tube turbine out of the powerhouse.

One of two 17A turbines we purchased from Celesty.

Luke Wright purchased Mat Bonacorsi's 18 Z from his widow. He did not need the throat piece. The 18Z from West Stockbridge did not have the throat piece. It was embedded in the old power house that was razed. It was a match in heaven? No, we did not check the Leffel "W" numbers. Our Z had bigger throat and runner diameters. When Will, Dave Flynn and Jay Lyons lowered our unit into the throat piece it was too big!!!! Will said, "Oh Well" and brought it back to the shop, installed it on our 60" Bullard and machined a 1/2 inch of the radius off of the throat ring. We painted the machined surface, brought it back to Tannery Pond, lowered it into the pit and "Viola!!!" it fit!!!

Chris Krueger purchased the site at Fiske Mills. The site had this extraneous draft tube lying around. Chris gave it to me. It became the nucleolus for the 18Z draft tube.

Here is the final product. Mike Piesyk at Industrial Steel and Boiler, 939 Chicopee Street, Suite 2, Chicopee, MA 01013-2893, (413)-532-7788, www.isbservices.com has taken the Fiske draft tube and the Bonacorsi throat ring and has married the two together with a little help from the God Vulcan!!!

The Shanack Foundry pieces arrive at the shop. The runner is a baby jewel!!! Thank you MTC. Thank you Amy Barad!!! The Shanak brothers also made a new 39" "Z" runner for the O'Connell Energy Group's Mini-Watt site in Orange, MA.

Another view of the Shanak Brothers new castings for our little 18 "Z" turbine. Bob and Ed Shanak are real craftsmen and a pleasure to do business with!!!

Here, Mike Piesyk is making the draft tube for the Leffel 17A. They rolled it in two half shells and subsequently welded it together along the longitudinal seams.

Mike Piesyk is loading the finished 17A draft tube into my poor F150. After hauling this 60 miles to Winchendon, I do not understand the acronymn, "Found on road dead"!!! The truck survived.

Here, I am dragging the new draft tube into the powerhouse.

Here, my fiancee, Karen Westerman, is checking to see if I am still alive! She has just finished painting the new Leffel 17A draft tube that we received from Industrial Steel and Boiler.

My exceptionally wonderful daughter, Celeste and my son in law Ronnie Johnson lowering the draft tube into the abyss.

The 17 A draft tube being rigged into place. Note the Leffel "Z" tube is already placed.

This is the hole I cut in the waterbox floor. I used our Thor rock drill to line bore 92, one inch diameter, holes in a rectangular pattern. I then used a rivet buster to punch out the spaces between the drilled holes. You can see the tailrace out the back side of the discharge pit.

Here I am looking into the discharge pit. You can see the 18 "Z" draft tube, on the left, hanging out of the Leroy Somers tube turbine's thimble. The Leffel Samson 17A draft tube is on the right. The 4x4 columns were used to hold the floor of the concrete form against the ceiling of the discharge pit.

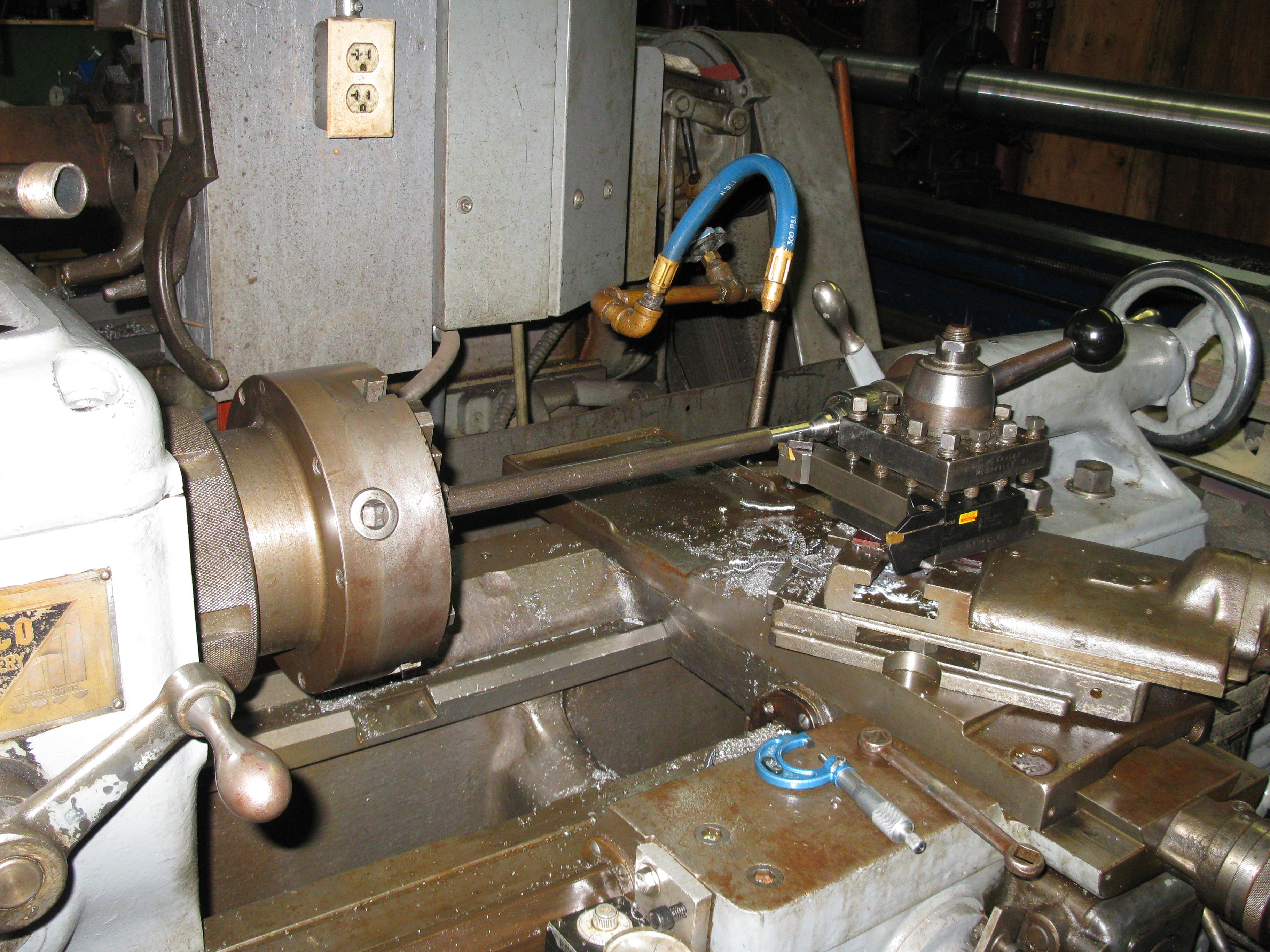

Here, Will Fay is machining the rough casting for the lower gate case of the Leffel "Z".

Here we are pouring 9 cubic yards of concrete across the powerhouse floor into the elephant trunk that is hanging off a chainfall. We had to chain the end of the chute to the top of the elephant trunk. We put huge wooden blocks underneath the front tires of the concrete truck to provide the height to get the concrete moving down the chute. Pouring concrete always makes me nervous. If you blow out a form it is a disaster. Not only do you waste your money but you have to jackhammer the mess out after it has set. All went well with our pour. Will and Ronnie did an outstanding job of constructing the forms.

Here, Johnnie Remington is holding the tail end of an elephant trunk. This is a dirty job. The concrete is very unwieldy when it drops 12 feet into the draft tube form. All went well.

Will and Johnnie in action!!!

Will Fay is operating the baby boring mill. He is machining the bottom gate casing. This used to be our large 60" boring mill. Now that I have finally gotten the 120 inch Niles Boring Mill operational this Bullard is relegated to baby boring mill status!!

Please see the following Picasa album detailing the 14 month effort to restore the Niles: http://picasaweb.google.com/frenchriverland/NilesBoringMillRebuild#

Will finished with the boring mill. He is now using the large Cincinnati/Bickford Radial Arm Drill to drill the holes and make the correct threads. Our shop is so compressed that the drill is adjacent to a workbench placed against the back wall. The 8 foot arm will not swing backwards. Will extended the radial drill's bed with two precision leveled aluminum beams so that he could reach all the holes.

Here is the broken 18 "Z" shift ring. Will used it as a template to drill the holes in the new casting. He clamped the two pieces together and located the holes with a transfer punch.

And, here is the freshly machined shift ring that Will crafted on the 60 inch Bullard. It is leaning up against the head stock end of the 36" by 30 foot long Poreba Roll Lathe.

Here, Marge Bailey is machining new bronge upper bushing nuts. Marge is our up and coming machinist. She is one of Warren's (The Wizard) many apprentices. Warren is keeping the legacy of machining in the US from becoming a lost art!!! Note the Lignum Vitae block in the Cincinnati Milling Machine in the background. Warren is making new quater block bearings for our Indian River HEP.

More of Marge Bailey's magic machining!!! Here, she is crafting wicket gate spindles (aka hinge pins) for the 18Z. Note the 10" diameter by 20 foot long billet in the Poreba lathe. It is the new mainshaft for the S. Morgan Smith camelback turbine, our No.2 unit at our Indian River HEP.

Here, "The Wizard" is dialing in and fastening the Leffel 18 "Z" so that Will can turn down the runner skirt ring to fit into its throat ring.We needed to put additional clamps on the bottom of the runner to prevent it from twisting out of the jaws. We ran into chatter when we were taking 0.050 inch cuts. We used planer jacks with long rods under the top lip of the skirt ring to stabilize the cut. We reduced the cut to 0.025 inches. The chatter stopped and Will got a good finish.

Dave Flynn, Jay Lyons and Will Fay have just loaded the Leffel "Z" runner into Jay's van. Please note the shiny band on the runner's skirt ring. We had already tried to install it and it was too big!! Major problem? "Oh well!!", No problemo!!! said Will. and he machined 1/2 inch off the skirt ring radius on the 60" Bullard!!! Will is soooo cool!!!

Chris Krueger is welding up the main support structure for the West Stockbridge, GE generator. We needed to span the former cylinder gate opening in the floor of the generating room. You can see our trashrack template leaning up against the back wall. We used it to fabricate the new racks.

Here, the major components are loaded onto Davis' trailer. This is just before I drove 1/2 mile and saw black smoke started pouring off one of the rear trailer tires!!! I had to come back to Turners Falls and remove the stator, rotor and head cover. I got to Winchendon after dark and had to back into the powerhouse with the back up lights on the Ford F-150. I swung Chris' frame onto the white crane and went home to bed. At 4:00 am the next morning I went back to Turners Falls and loaded the generator parts and went back to Winchendon. When I got there, Dave and Jay where already on site and unloading Kruegy's framework.

Jay and Dave off loading Kruegy's generator support frame. They had to fly it over the No. One TG set. Note the top of the generator rotor sitting on the trailer outside the door where I had just backed it down the power house driveway. The Sumitomo, Paramax gearbox and Kato gearbox on the No. One unit has given us exceptional service.

Looking down the hole from the generating room floor. You can see the Leffel "Z" runner now comfortably fits into its draft tube/throat ring.

Here, Will is using the great radial arm drill to drill and tap the back plate for the Leffell 17A speed increaser/generator support structure.

Here we are fitting the new Leffel "Z" gate case to its draft tube. We still need to give it a coat of paint and fit the eccentric pins.

Here, the Leffel 17A is fitted to its bed ring on top of the draft tube fabricated by Industrial Steel and Boiler of Chicopee, MA.

Here is the General Electric, 277 rpm, 480 volt, 40 KW hydro duty induction generator sitting on Kruegy's framework.

Here is the generator/gearbox combo for the little Leffel, Samson, 17A Francis turbine.

Here is the pile of old trash racks that we pulled from the forebay. In comparison is one of the new racks that was damaged because we lifted it with a choker in the center of the rack. The weight was too much and we crushed the sides. We used a different rigging method to subsequently lift them.

The new trash racks installed.

We still need to install the new switchgear and computers. We are also dredging the tailrace and making repairs to the dam. We are due to start up on December 31st of this year.

Beautiful Maura Hennessey has been helping Will and I with the final alignment on the Number Two unit at Tannery Pond Hydro. Previously, she helped me core two holes in the floor to insert the Number Three Unit's main shaft and governor shaft through the powerhouse floor. The 30 amp drill motor kept tripping the 20 amp breaker and Maura had to keep running across the powerhouse floor and resetting the breaker.

Here, I am making a mess of the powerhouse floor at Tannery Pond HEP. Maura and I are using the big Milwaukee Coring Machine to cut through the 12" thick powerhouse floor for the turbine shaft of the Number Three Unit to fit through. It was so cold that the cooling water was freezing to my boots and the floor at the same time!! I previously went down in the waterbox. I installed a stepladder over the Number Three turbine. I sat a Stanley "Fat Max" 5 beam laser on the top of the step ladder. I aligned the down looking laser over the center hole on the turbine shaft. I looked up at the uplooking beam and marked the spot on the ceiling. I climbed up the step ladder and using a Makita hammer drill, I drilled upwards and through the powerhouse floor to create a pilot hole to accurately align the coring drill over the turbine shaft. It worked perfectly!!

Mike Desrouche is making final adjustments to the new Tannery Pond HEP No. 2 generator. He is using a porta-power to move the bed beams that the generator is sitting on. The wooden blocks are sitting on the frame. As he pushes the blocks against the wall, the other block is pushing against the base of the generator stator. He is watching the two coupling halves slowly match up. He then used a Starret Master Precision Level to level the generator. We used the chainfall to lift the entire unit (generator, main shaft and runner), off the bed frame. He inserted different thickness stainless steel shims between the generator base and the frame to get the generator perfectly level. Mike works with me at my other company, Swift River Hydro Operations Company. He is the most prolific, hard working rigger, fitter/fabricator, inventor and plant operator I have ever encountered. The man never stops working!!

Will, and his baby sister, Lizzie, making final adjustments to the gate case at Tannery Pond. Note the red ratchet strap he has wrapped all the way around the gatecase to pull the gates into a closed position. He previously attached all 20 gate links to the nose of the wicket gates. Now he will insert the eccentric pins through the shift ring. He can then turn the eccentric pin until its end lines up with the hole in the opposite end of the link. He and Lizzie did this with all 20 eccentric pins. When they finished, they had a perfectly shut set of 20 gates. Years ago, before Dave Wright and I figured out this trick, we would assemble all the links and pins. We would then adjust one eccentric pin until its gate touched the next gate. Unfortunately, that made the gate you were working on open a gap with the previous gate. As you chased your way around the gatecase you gradually closed all the gaps. There was always one gate that still had a gap in it when you were done. It was time consuming and frustrating. Then the light bulb went on regarding the ratchet strap!!! Celesty, Karen, Maura and Lizzie are great sports to hang around on the weekends, in frozen hell, and help us rebuild our plant!!!! God bless Will, he has done most of the machining, all of the assembly and most of the rigging.

How do you get a 480 pound turbine mainshaft from my trusty and beat to heck, Ford F-150 without an external crane? You hook it to the electric chainfall and haul it out of the truck by brute force. The day before, I dropped off some tools, after a large snow storm. I tried to turn around in front of the powerhouse and my front wheels fell through the heavily crusted snow. I don't have four wheel drive and I was by myself. I ran three belts in series, shackled together and attached them to my trailer hitch. I hooked the other end to the 2 ton electric chainfall. I put the car in neutral and pressed on the up button. I dragged the truck back onto terra firma!! This time, my sweet heart Karen, is taking the pictures!!!

Here, Karen is inspecting the three TG sets at Tannery Pond HEP. Notice the main thrust bearing support plate recently installed beneath the No. 2 Unit.

April 25th, 2011, here, Marshall Smith of Smith Alternative Energy (www.smithtest.com) proudly poses in front of the newly installed switchgear for Tannery Pond HEP, on the Millers River, in Winchendon, MA. In the background is the newly installed generator control center. Marshall, his father, Ken Smith P.E. and his brother Ian Smith have designed and installed the electrical controls. It has been a trying process as they have also concurrently been designing and installing the control system for our Indian River HEP on the Westfield River, in Russell, MA. Three Allen Bradley SLC 500 PLCs automatically control the three TG sets. A continuous record of headwater, tailwater and bypass reach water levels is made for FERC verification.

Will and I posing for Karen in front of the No. 2 Unit at Tannery Pond HEP.

The newly completed No. Two unit at Tannery Pond HEP. Note all the details. Will Fay has designed, Auto Caded, machined, rigged in and installed the Main shaft, main shaft 1/2 couplings, shift arm turn buckle arms, governor shaft, governor shaft foot bearing, lignum vitae quarter blocks, nose bolts, eccentric pins, wicket gate pins, finished wicket gates, tie rod ends, tie rod bolts and wicket gate links. He has become and outstanding civil and mechanical engineer, machinist, business man and entrepreneur!!!!

Karen Westerman and Marshall Smith gaze in wonder at the newly installed switchgear at Tannery Pond HEP. Note the elaborate, large port, valve stack Marshall and Will installed on the Woodward Governor. They previously removed the flyball head to be able to install the four way valve. The valve is actuated by electric solenoids. The solenoids will be controlled by the Allen Bradley, SLC 500, programable logic controller.

Will Fay and beautiful Maura Hennessey in front of the newly finished No. 3 Unit at Tannery Pond. It is so difficult to wash Never-Seize from your hands!!!!

The best part of working on small hydro projects are our beautiful supervisors!!!

The supervisor girls are ecstatic!!!!

Will is determining the speed of Unit Two to allow for a soft start. The digital tachometer was not wired up yet so he used my father's Biddle tachometer. He had to catch the center of the spinning I- bolt.

Hi everybody, Will has energized Tannery Pond Unit Two for the first time! Here I have caught the drama of him throwing the breaker in!! Congratulations Will!!!!! It has been a long, productive and educational road!!

Maura Hennessey and Will Fay removing stop logs in the forebay at Tannery Pond. The waterbox had been empty for two years while Will replaced the trash racks and installed Units Two and Three. When Davis and I installed this 36 inch main carrying beam, and the vertical stop log channels, back in 1994, we installed them in front of the trash racks. This allows the racks to be replaced without draining Tannery Pond. Will and Maura started rock climbing last year. They have become quite strong!! It makes it easy to work the chain cum-a-long to pull the stop log panels.