|

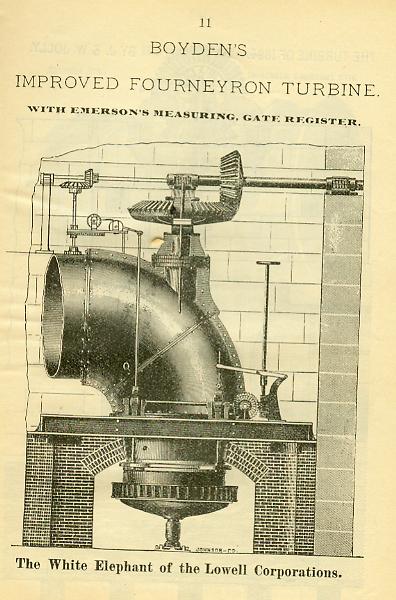

1852 FOURNEYRON PAGE

The ancestor of the modern, radial flow, turbine was invented by two French

Engineers, Claude Burdin (1790-1873) a professor at the Ecole des Mines at Saint

Etienne and his student, Benoit Fourneyron (1802-1867). In 1833, the Societe de

Encouragement pour le Industrie National, offered a prize to any person

producing a large scale, commercial hydraulic turbine. Fourneyron won the prize,

for his turbine design. The turbine was licensed to others to manufacture. In

1844, Uriah A, Boyden of Chicopee, Massachusetts modified and patented

improvements to the design. In 1849, he began to manufacture his turbine at the

Ames Manufacturing Company on the Chicopee River.

The earliest Boyden, Fourneyrons were installed in

Lawrence, Lowell and Holyoke, Massachusetts. These are the machines that James

Emerson refers to as the "Great White Elephants of the Lowell Corporation".

I had heard of these types of machines for years and did

not think any existed. We were doing routine maintenance on the Open Square's,

Leffel Z machines during the annual drawdown in Holyoke. I squeezed behind the

number four machine pressure case and found one of the original Boyden

Fourneyron machines in a dungeon. It is interesting that ten of these machines

were installed. They were decommissioned in 1888 when Holyoke Hercules, cylinder

gate machines were installed in two of the pits that had two of the Boyden

machines. Two more were removed in 1927 when the Leffel Z machines were

installed. The remaining six machines stayed tucked under the floor boards. To

the best of my knowledge, these are the only remaining Fourneyron turbines left

in the U.S.

"UPDATE-I":

"UPDATE-II": Please see the e-mail

sent to me by Mr. Tom Livoti of Cohoes, N.Y. inserted below my photographs.

(October 24, 2006)"

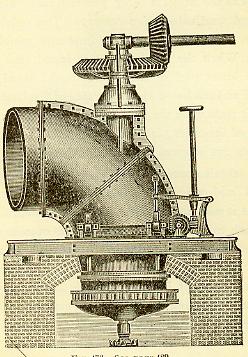

Boyden, Fourneyron Turbine. Note outward radial flow runner at bottom (buckets

just visible). The four bar linkage actuates a cylinder gate that is located

between the bottom of the pressure case and the inside of the runner. The water

sprays out radially and is directed into the tailrace by a circular, brick wall.

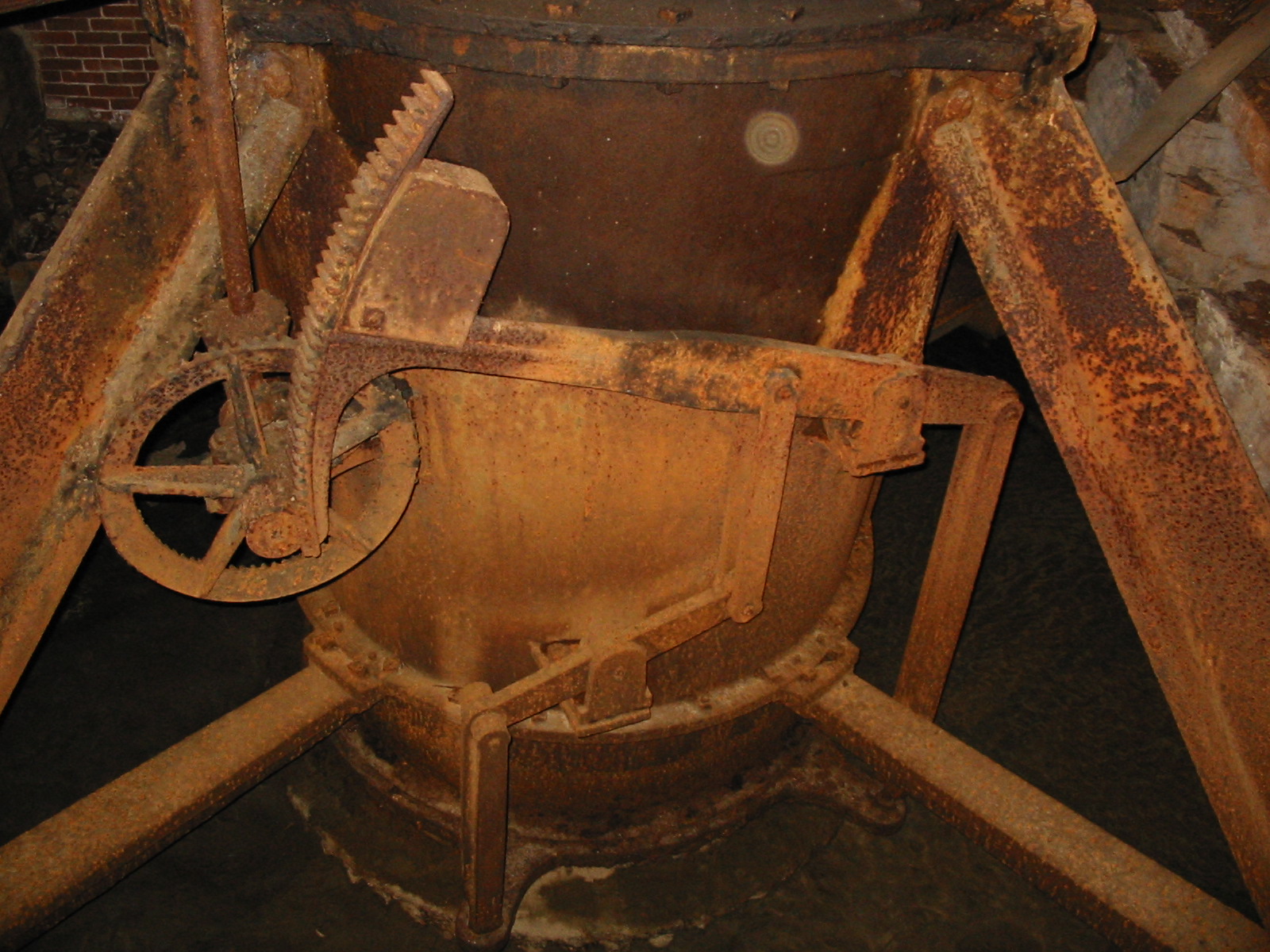

Boyden, Fourneyron runner. Note the runner consists of a large disc attached

to the bottom of the turbine shaft. The blades are attached to the edge of the

disc similar to a vertical cross flow runner. The rectangular bronze pieces are

the blades. The vertical control rods are attached to a cylinder gate that is

located between the inside of the runner and the pressure case. As the rods are

raised, the cylinder is lifted and the high pressure water is directed radially

through the blades.

A view of a second machine's runner.

A view of the curved, brick, discharge wall that directs the flow into the

tailrace.

Another machine with a good view of the radial outflow, external runner.

Here, my business partner, Ken Smith, is inspecting the 33 inch, Leffel "Z",

the reason we were at Open Square. In 1993, my other partner, Davis Hobbs and I

installed new wicket gates cast from a zinc alloy, ZA 12. 12 years later, there

is no corrosion and no fouling. These gates look like we installed them

yesterday.

*********UPDATE*********Between 1871 and 1873 these two Boyden

Turbines were installed at the Harmony Mill Number 3 in Cohoes, New York.

Harmony Mills was the largest They were used to power the mills machinery

via belts. These two turbines are installed in the south end of the mill

building. The water was supplied from a dam on the Mohawk River to a power

canal that fed the water in from the west side of the building. The water

was then channeled to other mills where it drove an additional three

turbines. The water flowed back into the Mohawk River after powering the

turbines.

These turbines produced 800 HP each based on a 102 inch diameter runner.

These photos show the only remaining Boyden Turbines in Cohoes, New York.

These photos are from October 19, 2006.

Mill Number 3 has been restored to Loft Apartments.

Thanks,

Tom Livoti

|  GREEN

GREEN